12 questions to ask before purchasing a media preparator.

A culture media preparator is a professional equipment specially designed to produce small or large quantities of culture media in microbiology and plant tissue culture laboratories. Its purpose, as the name implies, the preparation of high quality sterile culture media to which samples will be cultured for microbiological analysis, in the case of microbiology laboratories, or grow explants in the case of labs dedicated to plant tissue culture.

When considering purchasing a media preparator for your laboratory, it is crucial to assess its capabilities and to determine the level of after-sales service provided by the manufacturer, both prior to and following the acquisition.

In this article, we’ll walk you through the key aspects you should consider when investing in a media preparator. As you may have guessed, at RAYPA, we’d like to highlight the advantages of our AE-MP and TLV-MP series—because not only do we believe in their performance, efficiency, and return on investment, but we also know these systems inside out. Let’s get started.

Why should I purchase a media preparator?

Purchasing a media preparator represents a major investment. And while the investment typically yields a return in a relatively short amount of time, it nonetheless represents a substantial financial commitment. Therefore, it is important to consider the following questions before acquiring one:

1. Why does my lab need a media preparator?

Maybe you’re currently preparing large volumes of culture media manually using an autoclave, performing this task multiple times per week. If so, you already know how time-consuming, labor-intensive, and potentially risky this process can be. At RAYPA, we’ve spent over 15 years supporting labs just like yours—labs looking to automate and streamline this process. By switching to an automated solution, you can save time and money, reduce human error, improve consistency, and minimize occupational hazards.

That’s why we’ll be clear and direct:

allow you to carry out the five core phases of media production—preparation, sterilization, cooling, dispensing, and cleaning—in one single device. This integration helps you streamline workflows, minimize contamination risks, cut down overall processing time, and produce large volumes of sterile culture media thanks to an efficient heating system and rapid cooling at the end of the sterilization cycle.

2. What type of media will I be producing?

Not all laboratories prepare the same kind of media. In microbiology labs, it’s common to work with nutrient broths, agar plates, and selective or differential media.

With our media preparators, you can prepare any type of culture media, regardless of its composition. Additionally, you can safely prepare formulations containing heat-sensitive nutrients or antibiotics thanks to the dispensing port located on the lid. This feature allows you to add and dispense these components after the sterilization phase, preventing them from being exposed to temperatures above 70°C.

Another noteworthy feature is the ability to program multiple temperature segments during the preparation process, making it possible to produce more complex formulations such as chocolate agar.

Among the principal applications utilized by our customers, we observe the preparation of culture media for plant tissue culture, the preparation of Agar for qualitative microbiological analysis, and the preparation of lysogeny broth and buffer solutions for quantitative microbiological analysis.

3. What level of productivity can I expect? How long does a full cycle take?

As you might expect, it’s difficult to give a precise answer to this question, since both cycle duration and productivity depend on the specific media preparator model. As a general guideline, a full cycle typically takes between 50 and 125 minutes. If cycle time is a key concern for you, we offer high-performance models with up to 30 kW of electrical power that significantly reduce the heating phase—allowing for much shorter overall cycles.

In terms of productivity—meaning the volume of culture media that can be prepared per cycle—it ranges from 1 to 90 liters, depending on the selected media preparator model.

Media Coach Model | Culture media preparation capacity* min. – max. L |

|---|---|

AE-20-MP-10L | 1 – 8 |

AE-20-MP | 1 – 18 |

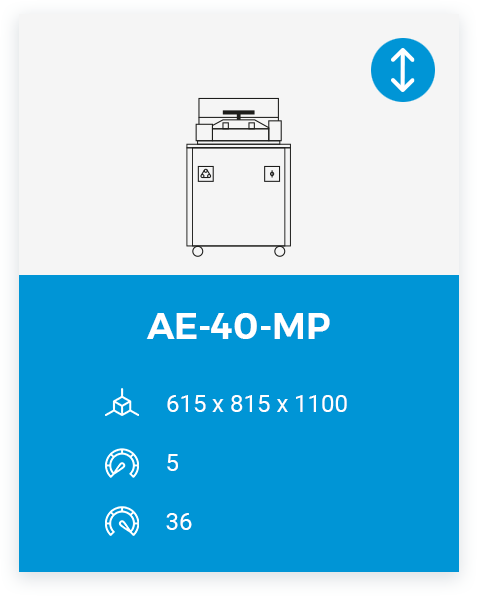

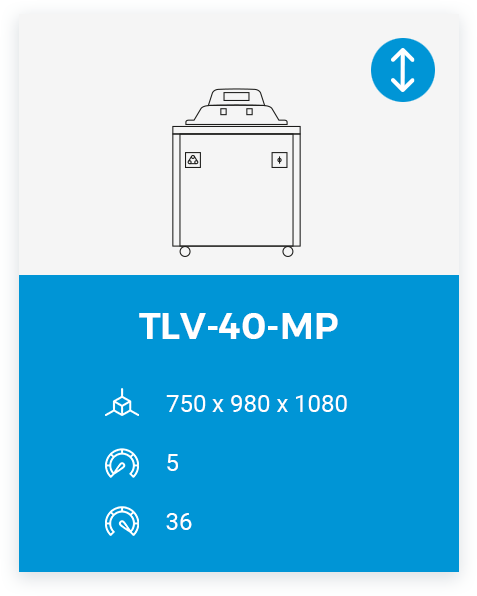

AE-40-MP | 5 – 36 |

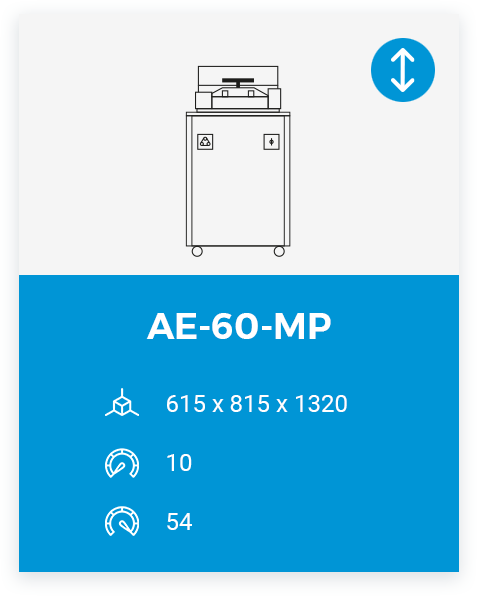

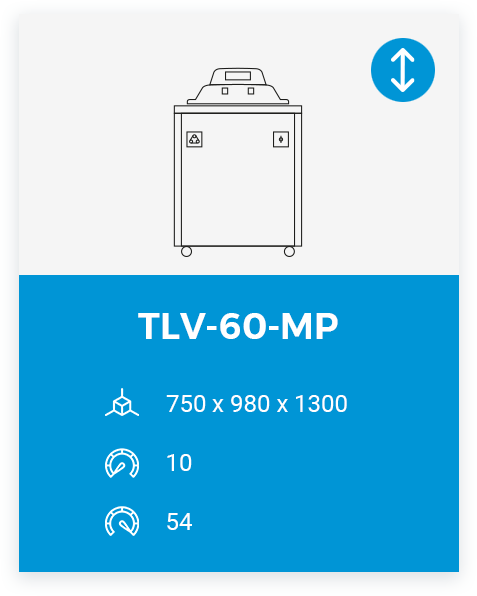

AE-60-MP | 10 – 54 |

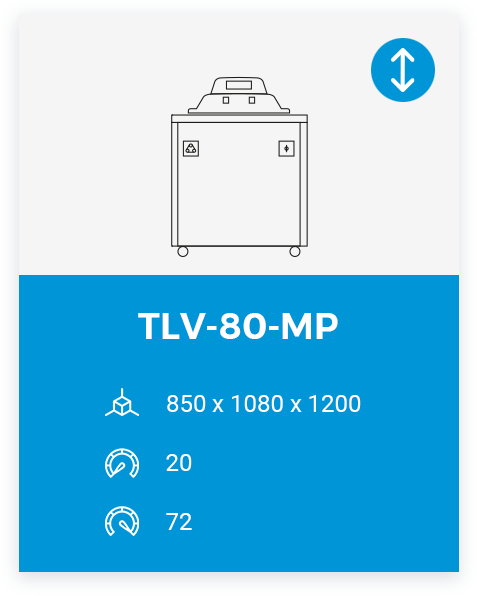

AE-80-MP | 20 – 72 |

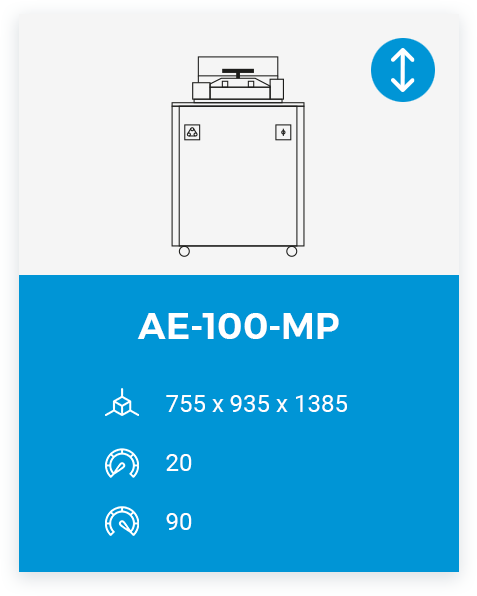

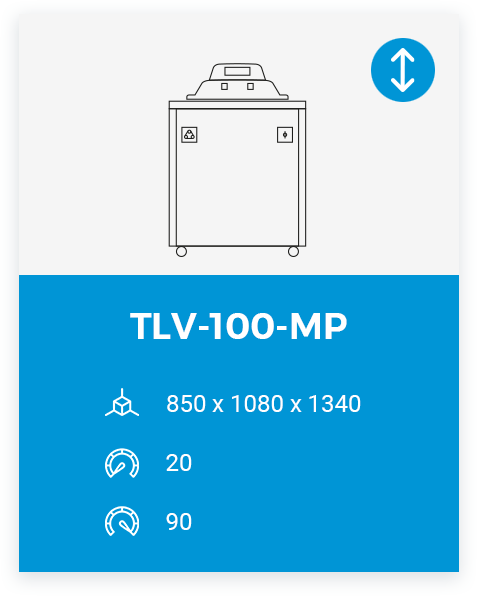

AE-100-MP | 20 – 90 |

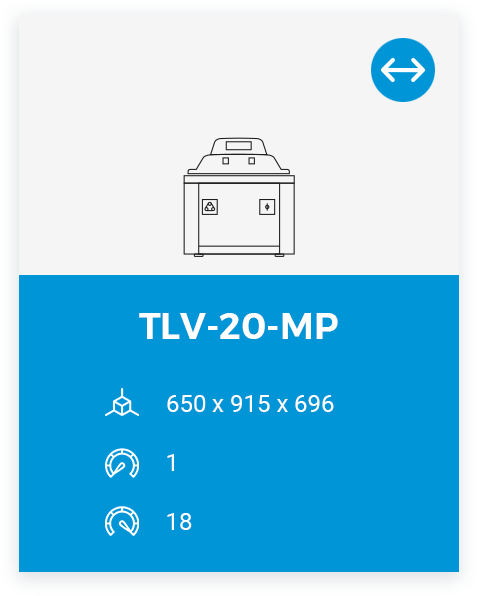

TLV-20MP | 1 – 18 |

TLV-40MP | 5 – 36 |

TLV-60MP | 10 – 54 |

TLV-80MP | 20 – 72 |

TLV-100MP | 20 – 90 |

Another key aspect to consider is the dispensing speed once the cycle is complete. In our media preparators, this ranges from 7 ml/s to 100 ml/s, depending on the selected dispensing mode.

4. What size media preparer does my lab need?

We offer a total of 11 models in various sizes, ranging from 8 to 90 liters in chamber capacity. The most important factor when choosing a media preparator is your production needs. It’s essential to consider not only your current requirements, but also your future growth.

On the other hand, there are 3 other aspects to consider before choosing a model and configuration: electrical and water connection requirements, available space and the consumption of resources such as electricity and water.

5. What options are available for dispensing the culture medium?

To select the appropriate dispensing mode, you first need to determine the volume of media required per container. For repetitive operations with small to medium volumes, your lab technician can dispense the sterilized media using the integrated peristaltic pump, operated via foot pedal. Additionally, each fill cycle can be programmed with a time delay to streamline the dispensing process.

In addition to the integrated peristaltic pump, all our models come with a set of two tubing sizes selected from a total range of five options (Ø 3.2 / 4 / 4.8 / 6.4 / 8 mm). If needed, a second peristaltic pump can also be added to your unit to double the flow rate. Depending on the tubing size and the number of pumps installed, the dispensing speed will range from 7 ml/s to 33 ml/s.

On the other hand, if your lab produces large volumes of culture media, our autoclaves allow you to operate with backpressure and an external dispensing station, achieving dispensing speeds between 65 ml/s and 100 ml/s. When using this dispensing mode, the system can be operated either via optical sensor or foot pedal.

For laboratories working with Petri dishes, we offer an automatic media dispensing system designed to carry out multiple processes in a fully automated manner, while ensuring advanced safety features. The dispensing area is protected by a safety cover and a UV-C lamp that guarantees sterility in the filling zone. We offer four models with capacities ranging from 101 to 241 Petri dishes, and a dispensing volume range from 1 mL to 1000 mL.

And finally, it is important to note that dispensing can be paused and restarted if necessary without compromising the integrity of the process. The dispensing lines are emptied by counterpressure, avoiding clogging of the tube due to gelation of the culture medium. All of this, without affecting the temperature of the culture medium, still inside the preparer, because it is maintained indefinitely at the established degrees Celsius.

6. What is continuous steam used for?

The continuous steam cleaning system is a key differentiating factor of our media preparer with the rest of the equipment on the market. Thanks to this innovative system, the dispensing lines can be automatically cleaned and disinfected with continuous steam at 100ºC. Cleaning the lines can be done before, during or after the dispensing phase. This feature greatly facilitates cleaning the inside of the lines.

In fact, many of our clients have told us that after disinfecting the dispensing lines in this way and working within a laminar flow cabinet, they typically don’t autoclave the dispensing lines anymore.

7. Is it possible to obtain lot-by-lot traceability?

With our media preparator, you can easily identify and configure the different stages of the media production process in a simple and automated way. You can also log batch numbers and manage user access control.

8. What connections are required to install the media preparator?

To install our media preparator in your laboratory you will only need:

Keep in mind that we offer a range of heating capacities—from 3 kW up to 30 kW—on our 80- and 100-liter models. These high-power configurations are especially useful for plant tissue culture laboratories that prepare large volumes of culture media.

A decalcified water network should be connected directly to the cooling water inlet that feeds the water cooling coils.

Regarding sterilization water, it’s worth noting that you can either manually add purified water by pouring it directly into the sterilization chamber, or automate the process by adding the KLL-MP automatic water filling accessory.

For draining the sterilization chamber, the cooling water, and, in some cases, the steam purge.

9. What kind of technical support and warranty are provided? Who is responsible for them?

What truly sets us apart—beyond the performance of our equipment—is the support we provide before and after the purchase of a media preparator. At RAYPA, we believe it’s essential for our staff to be directly involved in the design and manufacturing of our media preparators. In addition, our team of engineers is always available to support our customers. This level of involvement matters because, even though our systems are intuitive and easy to use, questions may still arise regarding installation, software, or maintenance.

Additionally, our technical service is always available to assist with any questions or technical issues, whether through a video call or on-site as necessary.

Additionally, after purchasing a media preparator, you will benefit from a 12-month warranty. Our commitment is to minimize any potential downtime in your laboratory in case of a breakdown. We have a wide range of spare parts in stock and, depending on your location, we may even provide you with a replacement equipment to ensure continuous operation.

10. Can the equipment be validated with IQ-OQ-PQ protocols?

RAYPA media preparators are industrial-grade laboratory equipment that should be calibrated and inspected periodically to ensure proper operation and performance. Additionally, if your laboratory operates under GLP or GMP conditions, we can confirm that equipment qualification is available and typically includes the following protocols:

- IQ which is the Installation Qualification

- OQ is the Operation Qualification

- PQ is the Performance Qualification

All three protocols are designed to generate objective documented evidence and demonstrate that the equipment has been properly installed, operates correctly, and performs as intended. We offer this service worldwide—either directly or through our network of authorized partners.

To carry out these qualifications, we not only review the equipment documentation, but also perform system tests under normal operating conditions as well as at operational limits to verify consistent and proper performance. This documentation is available to any of our customers upon request.

11. Are there any training courses in order to get the most out of my equipment?

Absolutely. After the purchase of a media preparator, RAYPA offers a commissioning service, along with personalized training sessions for customers upon request. These sessions can be delivered either on-site or online.

12. What is the manufacturing and installation lead time? When can I start using the equipment?

As a general rule, at RAYPA the manufacturing time for any of our media preparation models is usually 4 to 8 weeks. Although it can also be shorter if the reference is in stock.